Brushes in electric motor

The preparation of the blends required for the production of brushes begins with the selection of proven components (natural graphite powder, copper powder and binders) that are mixed in special blenders for a certain period of time until complete homogenization. After that, using a special pressing tool, we form a brush shape. Subsequent thermal treatment in furnaces with a protective atmosphere gives the required quality of brushes.

Our brush catalogs are presented below:

Brushes for cars, trucks and tractors

Brushes for cars, trucks and tractors

Brushes in electric motor

The preparation of the blends required for the production of brushes begins with the selection of proven components (natural graphite powder, copper powder and binders) that are mixed in special blenders for a certain period of time until complete homogenization. After that, using a special pressing tool, we form a brush shape. Subsequent thermal treatment in furnaces with a protective atmosphere gives the required quality of brushes.

Our brush catalogs are presented below:

Brushes for cars, trucks and tractors

Brushes for cars, trucks and tractors

Sinter bearings

The sinter bronze bearing has a wide range of applications. For the production of self-lubricating sinter bearings, we use mixtures of copper-tin based powders (bronze) and iron-copper or iron-graphite based powders. Pressing in special tools produces crude bearings which are subsequently heat-treated to a state of increased strength. The calibration procedure gives the final dimensions of the sinter bearing. Immersion in hot oil sinter bearings gives the final quality that it can work without additional lubrication. The impregnation volume ranges from 25-29% according to DIN 30910, Sint A50. During exploitation, this type of material, thanks to oil impregnation, develops a thin oil film between the shaft and the bearing.

Below are the catalogs

Sinter bearings

The sinter bronze bearing has a wide range of applications. For the production of self-lubricating sinter bearings, we use mixtures of copper-tin based powders (bronze) and iron-copper or iron-graphite based powders. Pressing in special tools produces crude bearings which are subsequently heat-treated to a state of increased strength. The calibration procedure gives the final dimensions of the sinter bearing. Immersion in hot oil sinter bearings gives the final quality that it can work without additional lubrication. The impregnation volume ranges from 25-29% according to DIN 30910, Sint A50. During exploitation, this type of material, thanks to oil impregnation, develops a thin oil film between the shaft and the bearing.

Below are the catalogs

Sintered metal filters

We produce bronze filters and 316L stainless steel filters. At the moment we can produce filters up to 40 mm high, although we plan to produce larger filters. Filters can be used to filter both liquids and gases and are very resistant to high temperatures, so they have great application.

Sintered metal filters

We produce bronze filters and 316L stainless steel filters. At the moment we can produce filters up to 40 mm high, although we plan to produce larger filters. Filters can be used to filter both liquids and gases and are very resistant to high temperatures, so they have great application.

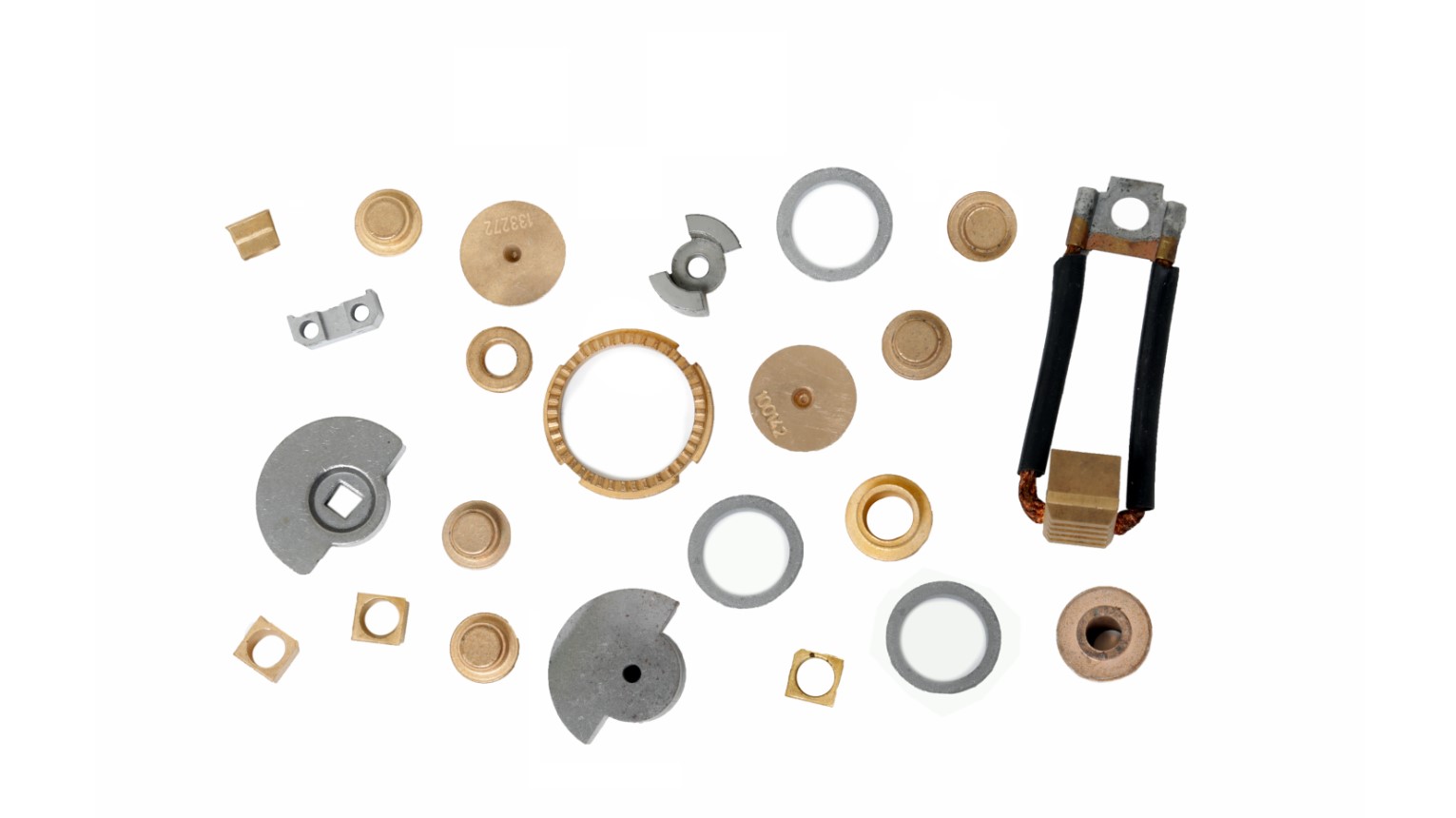

Sintered structural parts

Depending on the needs of our customers, we can also produce bronze and iron based structural parts. These are high density parts with enhanced mechanical properties, above all increased hardness and strength.

Sintered structural parts

Depending on the needs of our customers, we can also produce bronze and iron based structural parts. These are high density parts with enhanced mechanical properties, above all increased hardness and strength.

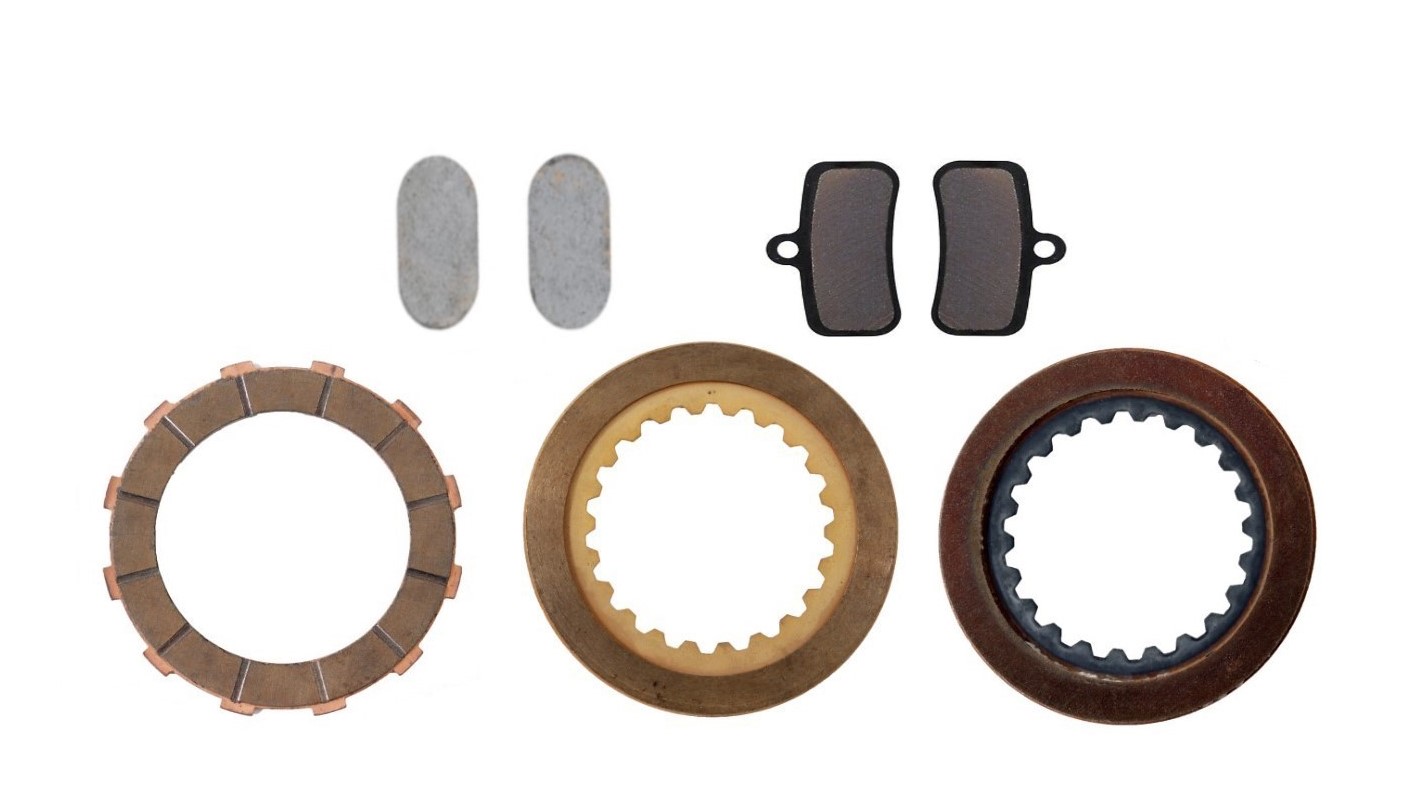

Friction slats

We offer friction blades for cultivators and bicycles.

Friction slats

We offer friction blades for cultivators and bicycles.

Powders

By selecting special qualities of metal powders and some non-metallic components, we have developed friction powder. Homogenization and pressing in special tools gives a friction layer which is bonded to the steel core by sintering under pressure and in a protective atmosphere. The friction layer obtained in this way is of high quality because it can work in oil and dry.

Powders

By selecting special qualities of metal powders and some non-metallic components, we have developed friction powder. Homogenization and pressing in special tools gives a friction layer which is bonded to the steel core by sintering under pressure and in a protective atmosphere. The friction layer obtained in this way is of high quality because it can work in oil and dry.